Introduction

Adrenochrome, a chemical compound derived from the oxidation of adrenaline, has gained attention in both scientific research and popular culture. Though its applications are somewhat niche, including its potential use in pharmaceuticals and research, establishing a dedicated Adrenochrome Manufacturing Plant presents a unique opportunity in specialized chemical production. This article outlines the key elements of an Adrenochrome Manufacturing Plant Project Report, offering insights into the project's feasibility, technology, financials, and more.

Project Overview

Objectives

The primary objective of setting up an Adrenochrome Manufacturing Plant is to produce high-quality adrenochrome efficiently and in compliance with industry standards. Key goals include:

- Meeting Market Needs: Addressing demand from research institutions and pharmaceutical companies.

- Economic Growth: Creating job opportunities and contributing to local and regional economies.

- Technological Innovation: Employing advanced technology to ensure high-quality production and operational efficiency.

Scope

The project encompasses several phases, from initial feasibility studies to full-scale production. Essential components include:

- Site Selection: Identifying a location with the necessary infrastructure and access to raw materials.

- Design and Engineering: Developing detailed plans for plant layout, equipment, and processes.

- Construction: Building the facility and installing the required machinery and systems.

- Operations: Managing day-to-day production, quality control, and distribution.

- Regulatory Compliance: Ensuring adherence to environmental regulations and industry standards.

Get a Free Sample Report with Table of Contents @

Technical and Operational Aspects

Technology

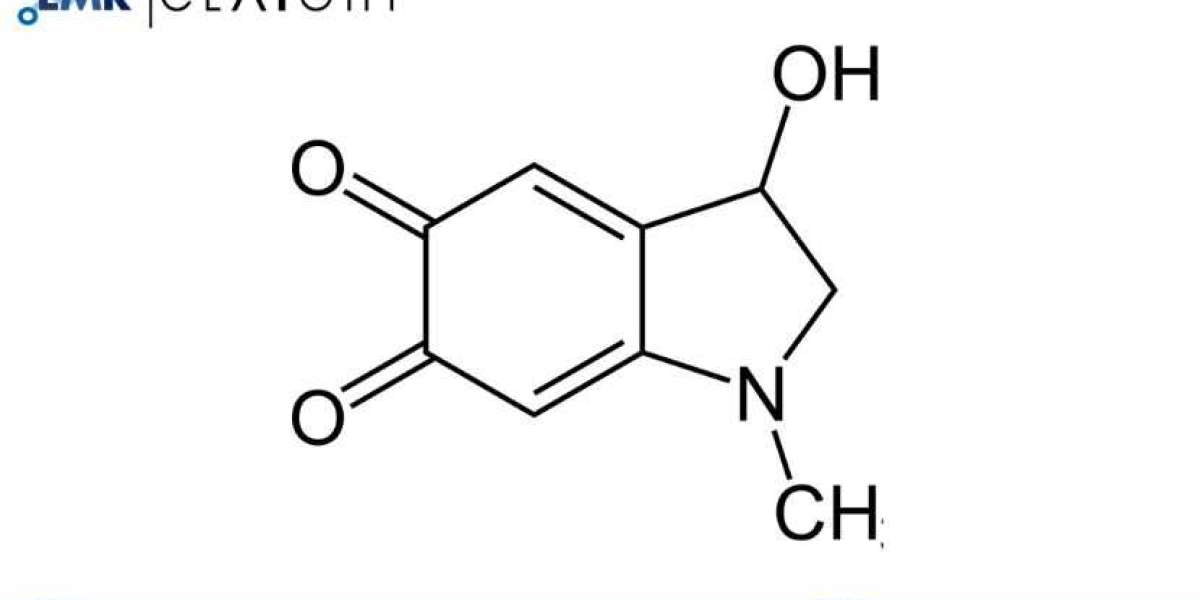

Adrenochrome is produced through the oxidation of adrenaline (epinephrine). The production process typically involves:

- Oxidation Reaction: Adrenaline is oxidized using specific reagents and catalysts to produce adrenochrome.

- Purification: The resulting adrenochrome is purified to remove impurities and achieve the desired quality.

Advanced technologies are employed to ensure efficiency and consistency in production. Key technologies include:

- Catalysts: High-efficiency catalysts to facilitate the oxidation reaction.

- Reaction Vessels: Specialized reactors designed to handle the oxidation process under controlled conditions.

- Purification Systems: Techniques such as chromatography to ensure the purity of the final product.

Equipment

Essential equipment for adrenochrome manufacturing includes:

- Oxidation Reactors: For conducting the oxidation reactions.

- Filtration Systems: To separate adrenochrome from reaction by-products.

- Distillation Columns: For further purification of adrenochrome.

- Storage Tanks: For storing raw materials and finished products.

Workforce

A skilled workforce is crucial for plant operations. Key roles include:

- Process Engineers: To design, optimize, and troubleshoot production processes.

- Chemists: For managing the chemical reactions and ensuring product quality.

- Technicians: To operate and maintain equipment.

- Quality Control Analysts: To test and ensure the purity and quality of adrenochrome.

- Administrative Staff: For overseeing plant operations, finance, and human resources.

Financial Considerations

Investment

The financial investment for establishing an Adrenochrome Manufacturing Plant includes:

- Capital Expenditure: Costs related to site acquisition, construction, equipment purchase, and installation.

- Operational Expenses: Ongoing costs for raw materials, labor, utilities, and maintenance.

Funding Sources

Funding for the project can come from various sources:

- Equity Investment: From private investors or venture capital.

- Loans: From banks or financial institutions.

- Grants and Subsidies: Potentially available for research and development projects.

Revenue Generation

Revenue is generated from the sale of adrenochrome to research institutions, pharmaceutical companies, and other specialized markets. Pricing depends on production costs, market demand, and competition.

Environmental and Safety Considerations

Environmental Impact

To minimize environmental impact, the plant must adhere to regulations and implement best practices:

- Emission Control: Systems to manage and reduce emissions of pollutants.

- Waste Management: Proper disposal or recycling of chemical waste.

- Energy Efficiency: Utilizing energy-efficient technologies to minimize consumption and reduce costs.

Safety Measures

Ensuring a safe working environment involves:

- Safety Training: Regular training programs for employees on handling chemicals and emergency procedures.

- Protective Equipment: Providing personal protective equipment (PPE) to workers.

- Emergency Protocols: Clear procedures for responding to accidents and chemical spills.

FAQs

What is adrenochrome used for?

Adrenochrome is used in various research applications and has potential pharmaceutical uses. It is also of interest in studies related to neurochemistry and psychiatry.

How long does it take to build an adrenochrome manufacturing plant?

The construction and commissioning of an adrenochrome manufacturing plant generally take between 18 to 36 months, depending on the project's scale, complexity, and regulatory requirements.

What factors are important in choosing a plant location?

Important factors include proximity to raw material sources, availability of infrastructure (such as transportation and utilities), compliance with environmental regulations, and access to skilled labor.

How can the plant ensure environmental compliance?

Compliance can be achieved by implementing effective emission control systems, managing waste properly, and following local and international environmental regulations.

What are the major risks associated with this project?

Major risks include fluctuations in raw material prices, changes in market demand, regulatory changes, and potential operational challenges. Proper planning, risk management strategies, and financial controls can help mitigate these risks.

Related Reports

https://www.expertmarketresearch.com/reports/united-states-augmented-and-virtual-reality-market

https://www.expertmarketresearch.com/reports/immersion-cooling-market

https://www.expertmarketresearch.com/reports/automotive-fabric-market

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: [email protected]

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au